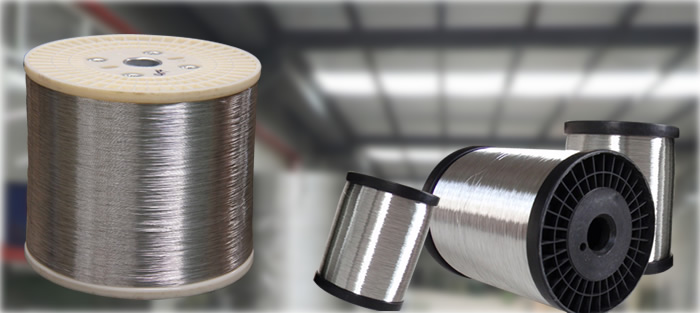

Aluminum and Aluminum Alloy Wire are supplied in a variety of aluminum and alloy grades.

The wire finds popular application in the following industries:

Weaving wire ;

Processing to the rivets, zipper, nails, meshes;

Welding wire ( Tig, Mig welding, all position welding);

Hose braiding materials, oil hose / hydraulic hose material for automotive and machinery;

Electronic industries and telecommunications industries;

Shield for power cable and various cables.

Wire diameter: 0.15-0.28mm

Technical Information of Aluminum (Aluminium) Wire:

| Model | Composition | ||||||||

| Silicon | Iron | Copper | Manganese | Magnesium | Chrome | Zinc | Ti | Ai | |

| 5056 | 0.80 | 0.40 | 0.10 | 0.05 -0.20 | 4.5 -4.8 | 0.05 -0.20 | 0.10 | micro | |

| 5154 | 0.45 | 0.45 | 0.10 | 0.10 | 3.1 -3.9 | 0.15 -0.36 | 0.20 | 0.20 | micro |

Mechanical Property:

| Wire Diameter(mm) | Tensile Strength (Mpa) | Elongation Rate % | Resistivity At 20°C (Ωmm2/m) |

| 0.22 | ≥230 | ≥12 | ≤0.054 |

| 0.20 | ≥230 | ≥10 | ≤0.054 |

| 0.18 | ≥220 | ≥9 | ≤0.054 |

| 0.16 | ≥220 | ≥8 | ≤0.054 |

| 0.15 | ≥220 | ≥7 | ≤0.054 |

| 0.12 | ≥220 | ≥6 | ≤0.054 |

Al Mg Alloy Wire is used for braiding and shielding of flexible coaxial cables, hydraulic hoses braiding, a variety of audio and videa cables, vehicle cable, network cable, data transmission cables and so on.

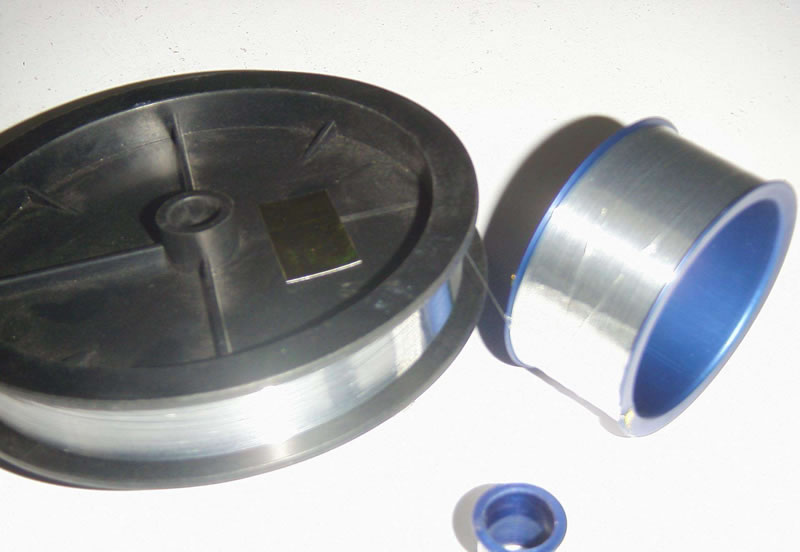

Aluminum alloy wire for cable, conductivity above 36%, aluminum grade: 5154, wire diameter: 0.12mm, tensile strength: 230-450MPA, elongation:7 to 15%, packed in 1kg spool or 3kg spool.

Feature:

Aluminum Magnesium Alloy Wire 5154 offers stable performance in high working temperature: high strength, excellent corrosion resistance, long life-span, allowable high surface load, small specific gravity, good formability and weldability.

Main Application:

Used in coaixial cable, HDMI cable, colored lights line, network cables and so on ( substitute of copper wire, and with better shielding effect).

| Item | 4 Inch | 5 Inch | 6 Inch | 7 Inch | 8 Inch | ||||

| Spool Material | PP/ABS | ||||||||

| Spool Weight | 0.1 kg | 1.8 kg | 0.33 kg | 0.46 kg | 0.72 kg | ||||

| NW Of Wire | 1.0±0.055 kg | 1.5±0.055 kg | 3.0±0.055 kg | 4.0±0.055 kg | 5.0±0.055 kg | ||||

| Rim Diameter | 105 mm | 130 mm | 160 mm | 185 mm | 200 mm | ||||

| Centre Circle Diameter | 18 mm | 24 mm | 35 mm | 35 mm | 76 mm | ||||

| 110 mm | 120 mm | 160 mm | 176 mm | 176 mm | |||||

Aluminum Alloy Welding Wire contains 5% magnesium additives, resulting in high intensity, favorable corrosion resistance and excellent color compatibility after anodizing. It is recommended to weld various grades of aluminum alloys which contain at most 5% magnesium and parts of wrought aluminum alloy of 5000 series, part of 6000 series, 7000 series, such as 5050, 5052, 5083, 5456, 6005A, 6061, 6063, 6082, 7005, etc.

Anodized Aluminum Wire, 1.2mm, for all-position welding with high intensity and low welding costs.

Features

1. High intensity

2. Low welding costs

3. Outstanding color compatibility after anodizing

4. Easy to operate. All-position welding.

5. Excellent corrosion resistance

ER5356 Welding Wire Chemical Composition

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr | Be | Other elements | Al |

| 0.25 | 0.4 | 0.1 | 0.05~0.2 | 4.5~5.5 | 0.05~0.2 | 0.1 | 0.06~0.2 | - | 0.0003 | 0.15 | Rem. |

Diameter, Weight and Length

Diameter(mm) | Weight Per Meter(g/m) | Length Per Spool(m) for Reference | ||||

| 0.5Kg | 2Kg | 5Kg | 6Kg | 7Kg | ||

| 1.2 | 3.02 | 165 | 662 | 1655 | 1987 | 2813 |

| 1.6 | 5.37 | -- | -- | 931 | 1117 | 1304 |

Specifications and Packing

| Spool Size | Weight | Specifications |

| D300mm | 6Kg~7Kg | 0.8mm, 0.9mm, 1.0mm, 1.2mm, 1.6mm |

| D270mm | 5Kg~6Kg | 0.8mm, 0.9mm, 1.0mm, 1.2mm, 1.6mm |

| D200mm | 2Kg | 0.8mm, 0.9mm, 1.0mm, 1.2mm |

| D100mm | 0.5Kg | 0.8mm, 0.9mm, 1.0mm, 1.2mm |

MIG or TIG Aluminium Welding Wires ER4043

Welding wire/TIG Aluminium welding wires ER4043

1) Typical composition of high grade titanium tig welding wire (%)

| Si | Fe | Cu | Mg | Mn | Zn | Be | Ti |

| 4.50--5.50 | <0.80 | <0.30 | <0.05 | <0.05 | <0.10 | <0.0003 | <0.20 |

2) Classification of high grade titanium tig welding wire :

GB/T 3190--1996

GB/T 10858--1989-----HS311

AWS A5-10 ---------ER4043 professional titanium tig welding wire.

3)Physical properities of high grade titanium tig welding wire (Approx Value):

Test temperature(oC)----20

Tensile strength Rm(MPa---120

Elongation A5(L0=5d0)(%)-8 0.2%

yield strenth Rp0.2(MPa)-40 professional titanium tig welding wire.

4)Application:

Aluminum TIG welding wire is one type of products can be use in forging and casting alloys welding due to it has silicon of 5% with the good performance in anti-thermalcrack

The argon arc welding of Aluminum alloy casting and workpiece is used as the filler material, special for 6061 and 6XXX series aluminum alloy, and 3XXX & 2XXX series aluminumalloy welding, widely used in ships, engine, chemistry, food, sports, uipment, mould, furniture, vessel, container, etc.

ER4043 aluminum & silicon is with high of crack resistance, but low plasticity, so for Plastic deformation joints after welding, we donor suggest it. You should strictly clean the oxide film on the edge of the workpiece and oil before welding, otherwise it will make bad weld produce and cause porosity, slag inclusion and other defects. Also you can use a plate to hold molten metal to ensure meld form.

5) Product useage:

Aluminum TIG welding wire is widely applied in ships , engine, chemistry, food, sports equipment, mould furnitures,vessel, container etc.

Welding wire/MIG Aluminium welding wires ER4043 Advantages:

1. Little Spatter

2. Excellent welding process

3. Very good for machinable

4. Pure nickel core

5. Both AC and DC applicable

6. Weldment: no need to preheat, good crack resistibility and process-ability professional titanium tig welding wire.

For mesh weaving and other manufacturing uses.